Replacement carbide tips provide ultimate strength and durability while utilising the existing steel body maintains cost-effectiveness. Resharpening the tips then brings the tooling back to its original specs. Simply put, this service renders old tooling as good as brand-new!

The moment a tool is worn, you are already losing. Retipping means efficient tool management, cost-reduction and improved profit. By reconditioning tools to their primary dimensions via replacing the carbide blades, including helical tips and regrinding to the tool’s original dimensions; UTT's retipping service restores original performances by 100%.

Need something fast that you can’t buy off the shelf? Give us a call. We can repair or replace your tooling in order to minimise your downtime and keep your production lines running.

Our investment in the latest in-house inspection technology, with equipment calibrated to an exacting standard, means tolerances are microscopic and flawless.

Return on investment and profitability are of course key drivers and we know that. By retipping, regrinding or coating your tooling you will extend their life and maximise cost effectiveness.

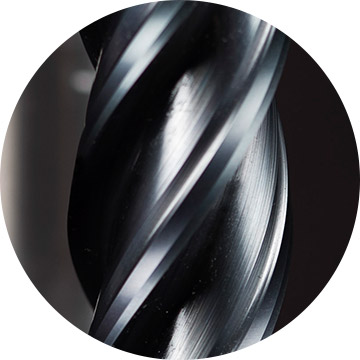

Brazed Carbide works using a solid steel body and carbide tip; the steel drives, while the carbide tip slices with ultimate precision.

Solid Carbide is an excellent option for process security, manufacturing cost-effectiveness and high-grade hole quality.

High-speed steel (HSS or HS) - a class of high alloy steels - are capable of withstanding higher temperatures without losing temper.

Whatever industry you may be in, if you want to work with a tooling company you can trust, then look no further. We are skilled, experienced and knowledgeable; so please give us a call on 0116 2347 840 or drop us an enquiry: