By reducing friction, oxidation risks and general wear, we enable your tools to perform to the absolute best of their abilities. Tool coating also aids in lowering metal fatigue and increases thermal resistance as well.

Furthermore, the various coatings utilised in our recoating service successfully enhance tool performance, providing a new lease of life when combined with our refurbishing services.

Coated tools speed up production and diminish overall costs. Reducing machining times coated cutting tools can be worked with considerably higher cutting parameters than uncoated ones; this cuts expenses significantly. Extended tool life means fewer tool replacements; therefore reducing manufacturing costs.

Need something fast that you can’t buy off the shelf? Give us a call. We can repair or replace your tooling in order to minimise your downtime and keep your production lines running.

Operating within your stipulated parameters, we'll design your specific tooling package. We'll complete the job with precision, and rapid turnaround time; optimising your productivity and profitability.

Return on investment and profitability are of course key drivers and we know that. By retipping, regrinding or coating your tooling you will extend their life and maximise cost effectiveness.

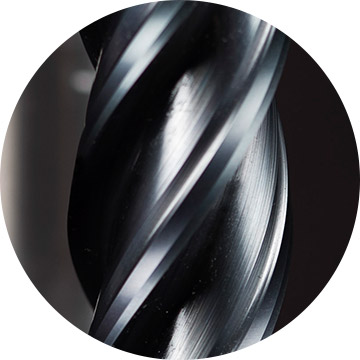

Brazed Carbide works using a solid steel body and carbide tip; the steel drives, while the carbide tip slices with ultimate precision.

Solid Carbide is an excellent option for process security, manufacturing cost-effectiveness and high-grade hole quality.

High-speed steel (HSS or HS) - a class of high alloy steels - are capable of withstanding higher temperatures without losing temper.

Whatever industry you may be in, if you want to work with a tooling company you can trust, then look no further. We are skilled, experienced and knowledgeable; so please give us a call on 0116 2347 840 or drop us an enquiry: